Contact: Manager Zhang 13823551369

Manager Chen 13316540440

Mail box: 3265465343@qq.com

Fax: 0755-84826339

Website: www.szhtgj.cn

Address: 3020, Longcheng Avenue, Longgang District, Shenzhen, Guangdong Province

Introduction to Condensation Mold Silicone:

Condensation mold silica gel is commonly known as industrial grade silica gel. Its environmental protection is as good as addition mold silica gel. It is a liquid silica gel material suitable for industrial mold making. The AB two-component ratio is 100:2~2.5, which belongs to room temperature vulcanization molding silicone rubber.

Condensation mold silicone use:

Condensation mold silicone is mainly used in toy gift industry, craft gift industry, resin crafts industry, unsaturated resin crafts industry, Buddha sculpture crafts, plaster craft gift industry, furniture decoration industry, character reproduction, architectural decoration industry, candle craft, Plastic toy industry, gift stationery industry, mold manufacturing industry, Polly industrial products, simulation animal plant sculptures other industries of product replication mold making.

Condensation mold silicone features:

1. Good fluidity, easy demoulding, easy foaming;

2. There are many times of mold turning, the service life of silicone mold is long;

3. Good tear resistance, strong tensile resistance, the finished mold can be used for a long time without deformation;

4. Compared with addition molding silica gel, the price is cheaper.

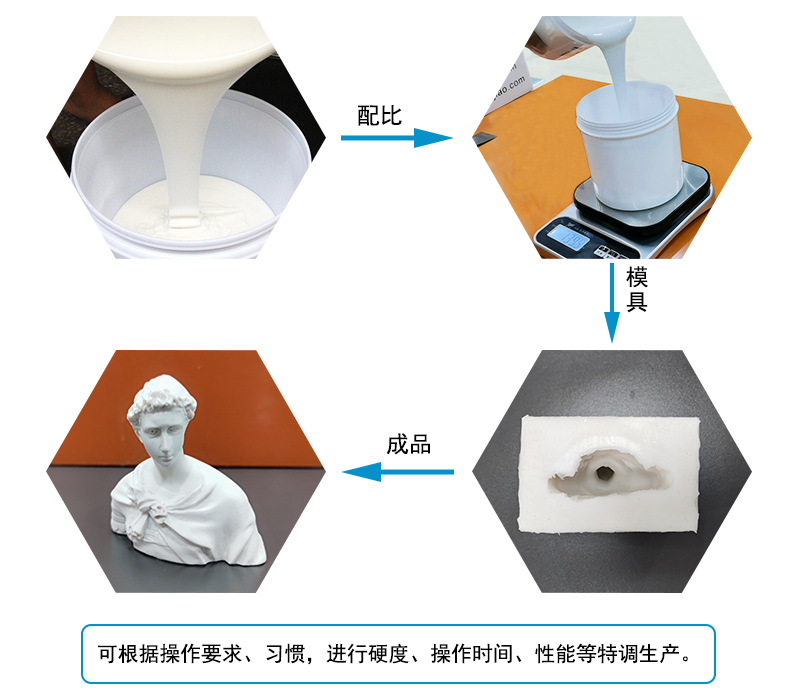

Condensation mold silicone operation:

1. Mix the condensation mold glue curing agent at a weight ratio of 100:2~2.5 to mix stir evenly;

2. Put the mixed evenly mixed silica gel into a vacuum machine to vacuum remove bubbles. The advantage of this is to make the finished product smooth bubble-free. (If there is no vacuum machine, the curing time can be extended the bubbles can be discharged naturally, but the effect is ideal);

3. Spray (coating) a layer of release agent on the already made mold mold frame, fix the mold in the middle, slowly steadily pour the bubbled liquid silicone into the mold frame until the silicone is completely Cover the mold, then wait for it to completely solidify;

4. After the mold silicone is completely cured, the mold can be demolded, the silicone mold is taken out for edge treatment.

5. Generally, the silica gel mold is recommended to be put into use after being placed for 24 hours, which can exert the good use effect of the mold.

Note on operation of condensation mold silicone:

1. It is recommended to add silicone oil during the operation. If you have to add it, please consult your supplier for the proportion of addition. Do add it yourself, which may cause the performance of silicone to decrease;

2. The proportioned silica gel should be used up within the operating time as soon as possible to avoid waste of raw materials;

3. The silica gel curing agent must be mixed evenly to prevent the phenomenon that the silica gel does cure;

4. This product belongs to condensation mold silicone, cannot be mixed with addition molding silicone.

Contact: Manager Zhang 13823551369

Contact: Manager Zhang 13823551369

Manager Chen 13316540440

Mail box: 3265465343@qq.com

Mail box: 3265465343@qq.com

Fax: 0755-84826339

Fax: 0755-84826339

Address: 3020, Longcheng Avenue, Longgang District, Shenzhen, Guangdong Province

Address: 3020, Longcheng Avenue, Longgang District, Shenzhen, Guangdong Province

|  | |

| Hongtu Mobile Station | Ali shop |