Contact: Manager Zhang 13823551369

Manager Chen 13316540440

Mail box: 3265465343@qq.com

Fax: 0755-84826339

Website: www.szhtgj.cn

Address: 3020, Longcheng Avenue, Longgang District, Shenzhen, Guangdong Province

Brief introduction of prototype mold silicone:

Prototype mold silicone is also called prototype silicone. Compared with conventional mold glue, the price is low, the number of re-molding is high. Generally, it may be about 20 times, while the number of conventional mold silicone re-molding can reach thousands of times. Therefore, prototype silica gel is mainly used for model development of various products small batch production.

Shouban model mold silicone use:

Hand model mold silicone is widely used in the production of hand model molds, handicraft model design, PVC plastic molds, alloy toy crafts, plastic toys, low melting point alloy product mold production, simulation product model replication, shoe sole mold manufacturing, electronic equipment earthquake resistance, pad printing Development of product models such as positioning.

Features of hand model mold silicone:

1. Low viscosity, good fluidity convenient operation;

2. It is limited by the thickness of the product can be deeply cured;

3. Low price cost saving.

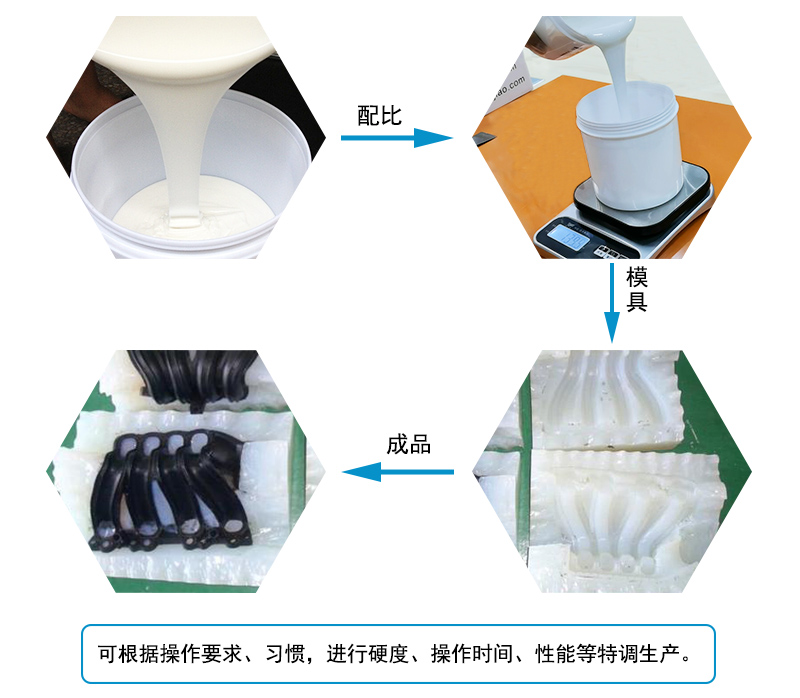

Hand model mold silicone operation:

1. The silica gel a certain amount of curing agent are mixed according to the proportion, the mixing can be manually stirred mixed with equipment;

2. The mixed rubber should be defoamed before filling the mold. During the degassing process, the volume of the rubber compound will increase by 4-5 times, so the volume of the degassing container is 4-5 times larger than that of the rubber compound, the colloid will return to normal after about 10 minutes. When no bubbles escape on the surface Time can be completed.

3. The surface of the model product the surface of the material model to be contacted by the rubber material needs to use liquid paraffin surfactant as a release agent.

4. The curing of the model after mixing degassing requires a certain temperature time, such as curing at 120±5°C for 30 minutes, curing at 60~70°C for 2 to 3 hours, curing at room temperature for 24 hours.

Hand model mold silicone operation note:

1. After making the product with hand-made silica gel, wait for 24 hours before putting it into production;

2. During the stirring process, the silicone curing agent must be fully stirred evenly, the vacuuming time should be too long to avoid curing of the silicone during vacuuming.

Hand model mold silicone parameters:

color | White/Translucent | |||||

Hardness (Shaw A) | 15±2 | 20±2 | 25±2 | 30±2 | 33±2 | 40±2 |

Vulcanizing agent addition (%) | 2-3 | |||||

Dynamic viscosity (mPa.s) | 1.3w±0.2w | 1.7w±0.2w | 2.5w±0.2w | 2.7w±0.2w | 2.5w±0.2w | 1.5w±0.2w |

Tensile strength (MPa) | 2.5 | 2.8 | 3.4 | 4.0 | 3.5 | |

Tearing strength (KN/m) | 16±2 | 19±2 | 24±2 | 25±2 | 21±2 | |

Elongation(%) | 380 | 530 | 410 | 420 | 450 | 180 |

Density (g/cm³) | 1.08 | 1.09 | ||||

Operating time (min) | 30-50 | 30-40 | 30-50 | |||

Curing time (h) | 4-5 | 3-4 | 4-5 | |||

Linear shrinkage rate (%) | 0.3 | |||||

standard packaging | 25kg | |||||

Note: The above parameters are only regular parameters. If you have special requirements, please contact our company; the hardness, viscosity, operating time after curing can be specially adjusted provided according to customer needs.

Contact: Manager Zhang 13823551369

Contact: Manager Zhang 13823551369

Manager Chen 13316540440

Mail box: 3265465343@qq.com

Mail box: 3265465343@qq.com

Fax: 0755-84826339

Fax: 0755-84826339

Address: 3020, Longcheng Avenue, Longgang District, Shenzhen, Guangdong Province

Address: 3020, Longcheng Avenue, Longgang District, Shenzhen, Guangdong Province

|  | |

| Hongtu Mobile Station | Ali shop |