Contact: Manager Zhang 13823551369

Manager Chen 13316540440

Mail box: 3265465343@qq.com

Fax: 0755-84826339

Website: www.szhtgj.cn

Address: 3020, Longcheng Avenue, Longgang District, Shenzhen, Guangdong Province

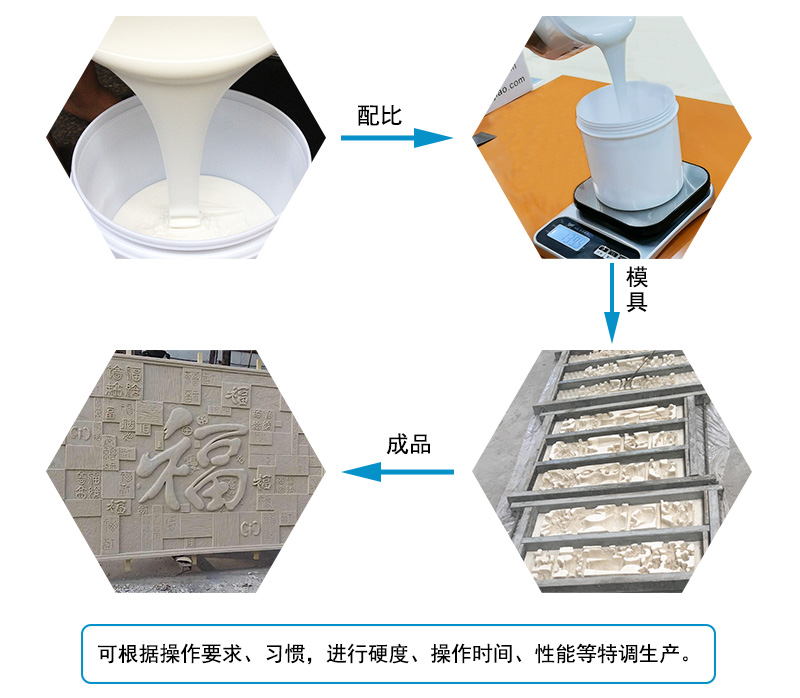

Introduction of Sandstone Relief Mold Silicone:

Sandstone relief mold silica gel is a two-component mold silicone rubber that is exquisitely made of polymer materials such as quartz sand. It is divided into two-component AB has fine no impurities.

Use of silica gel for sandstone relief mold:

Sandstone relief mold silica gel is suitable for remolding various sandstone artworks, garden decorations, outdoor sculptures, artificial sandstone stones, garden sculptures, relief murals, shaped cultural stones, etc. The recommended hardness range is 15-40 Shore degrees, the final hardness value is determined according to customer product requirements processes.

Features of sandstone relief mold silicone:

1. The made silicone mold does deform expand;

2. It has the advantages of high temperature resistance, acid alkali resistance, corrosion resistance;

3. It has the advantages of good weather resistance, many times of mold turning, long service life of silicone mold;

4. Low shrinkage rate (≤0.3%), fast curing molding at room temperature, performance can be adjusted according to customer requirements;

5. Suitable for all kinds of large, medium small, complex-shaped product replication silicone mold making.

Sandstone relief mold silicone operation:

1. Spread a layer of release agent (Vaseline) evenly on the surface of the glass plate. The release agent can also be replaced with detergent soapy water. Blow the dust on the glass plate with an air gun;

2. According to the structure, pattern purpose of the product, the appropriate silica gel for the ratio. Here, choose the mold glue of Hongtu HT-8830 for the ratio (100: 2-2.5);

3. Use a mixer to mix the silica gel evenly then put it in a vacuum machine to vacuum;

4. Vacuum to -0.1mpa, can make the finished mold without bubbles. If there is no vacuum machine, the added amount of curing agent can be reduced, the curing time of silicone rubber can be prolonged, the excess bubbles can be released;

5. After vacuuming, pour all the silica gel into the mold, apply evenly, blow off the bubbles on the silica gel with an air gun;

6. After the silica gel is dry for about 15 minutes, apply for the second time, repeat the first application steps, usually 2-3 times, the specific number of layers depends on the size of the product;

7. When the silicone is flowing, spread a layer of gauze on the silicone mold;

8. After painting, put on the tenon close the mold, so that the mold is in good position;

9. Clean the edges of the dried silicone mold, fix the shape of the outer mold with a wooden board;

10. Pour the adjusted plaster into the wooden board apply it neatly. After the outer mold is cured, remove the outer mold;

11. Use scissors to trim the burrs around the silicone mold, now a relief silicone mold is completed. The mold is placed in production for 24 hours.

Note on the operation of sandstone relief mold silicone:

1. Use clean operating tools to prevent silica gel mixing with impurities affecting curing;

2. The amount of curing agent added should depend on the temperature, it will decrease if the temperature is higher. Excessive addition of curing agent will affect the quality of the mold, the silicone mold will become brittle; adding less curing agent will prolong the curing time;

3. Vacuum to -0.1mpa is enough, the vacuum time should be too long to prevent cross-linking reaction of silica gel when vacuuming, causing silica gel to become piece by piece, causing waste of raw materials;

4. After making the silicone mold, store it in a ventilated, cool dry place, put it into production after 24 hours.

Sandstone relief mold silicone parameters:

color | White/Translucent | |||||

Hardness (Shore A) | 15±2 | 20±2 | 25±2 | 30±2 | 33±2 | 40±2 |

Vulcanizing agent addition (%) | 2-3 | |||||

Dynamic viscosity (mPa.s) | 1.3w±0.2w | 1.7w±0.2w | 2.5w±0.2w | 2.7w±0.2w | 2.5w±0.2w | 1.5w±0.2w |

Tensile strength (MPa) | 2.5 | 2.8 | 3.4 | 4.0 | 3.5 | |

Tearing strength (KN/m) | 16±2 | 19±2 | 24±2 | 25±2 | 21±2 | |

Elongation(%) | 380 | 530 | 410 | 420 | 450 | 180 |

Density (g/cm³) | 1.08 | 1.09 | ||||

Operating time (min) | 30-50 | 30-40 | 30-50 | |||

Curing time (h) | 4-5 | 3-4 | 4-5 | |||

Linear shrinkage rate (%) | 0.3 | |||||

standard packaging | 25kg | |||||

Note: The above parameters are only regular parameters. If you have special requirements, please contact our company; the hardness, viscosity, operating time after curing can be specially adjusted provided according to customer needs.

Contact: Manager Zhang 13823551369

Contact: Manager Zhang 13823551369

Manager Chen 13316540440

Mail box: 3265465343@qq.com

Mail box: 3265465343@qq.com

Fax: 0755-84826339

Fax: 0755-84826339

Address: 3020, Longcheng Avenue, Longgang District, Shenzhen, Guangdong Province

Address: 3020, Longcheng Avenue, Longgang District, Shenzhen, Guangdong Province

|  | |

| Hongtu Mobile Station | Ali shop |