Contact: Manager Zhang 13823551369

Manager Chen 13316540440

Mail box: 3265465343@qq.com

Fax: 0755-84826339

Website: www.szhtgj.cn

Address: 3020, Longcheng Avenue, Longgang District, Shenzhen, Guangdong Province

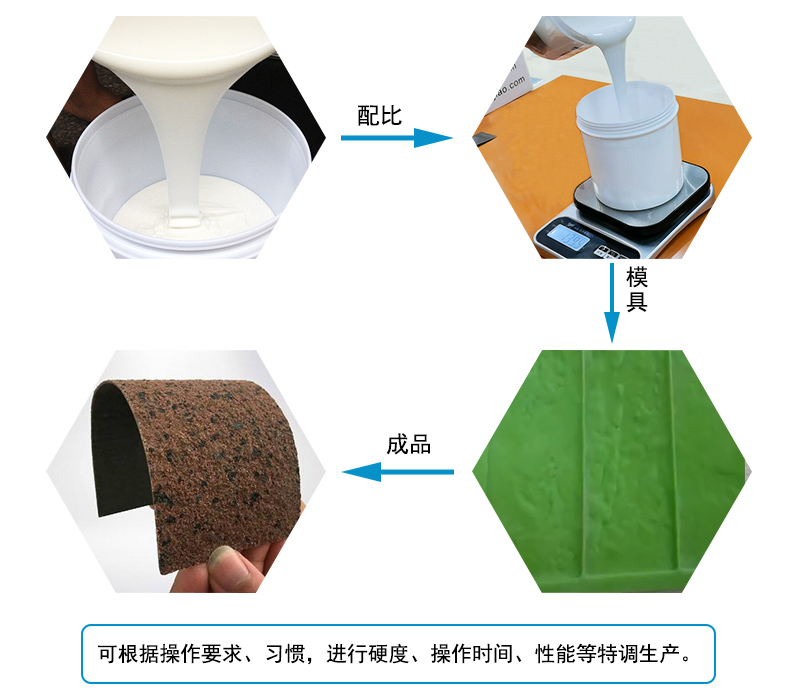

Introduction of soft porcelain mold silicone:

Soft porcelain mold silicone is also called two-component room temperature vulcanized silicone rubber. It has good fluidity strong maneuverability. The surface of the mold made of this type of silicone is smooth, the number of mold turns is large, the silicone mold has a long service life.

Uses of soft porcelain mold silicone:

Soft porcelain mold silica gel is suitable for reversal molding of cultural stone, sand sculpture sandstone artwork, large-scale urban garden sculpture. It is widely used for exquisite mold reproduction, resin, poly, plaster, candle, handmade soap other mold making.

Features of soft porcelain mold silicone:

①Good fluidity, good operability easy demoulding;

②High temperature resistance, acid alkali resistance, good tensile force, no expansion;

③Low shrinkage rate, the mould made is deformed;

④There are many times of mold turning, the service life of silicone mold is long;

⑤The performance is adjustable, the silica gel can be customized on demand.

Method for making silicone molds for soft porcelain exterior walls (generally, there are two methods for making soft molds):

Pouring method (pouring mold): The prototype is directly embedded in the mold rubber, the prototype is taken out after vulcanization to obtain a silicone rubber female mold. It is necessary to strictly control the generation of bubbles when using this method to pour the mold. Because the thickness of the entire mold is uniform, it takes a long time to cure the mold.

Layering method (brushing mold): First coat a certain thickness of mold glue on the surface of the prototype, then increase the mold thickness layer by layer. This can greatly reduce the amount of mold glue, reduce production costs, reduce the quality of the female mold.

The working temperature of the mold silica gel is less than 160 degrees, the drying time of each spray coating liquid is 40-60 minutes. After the first layer of glue is dried (the thickness of each spray, coating, brushing cannot exceed 0.6 mm, the drying time will be extended Many; spray, paint brush evenly, brush out the recessed part of the workpiece if the thick glue is too thick, so as to avoid the drying curing time of the thick glue is too long, which will affect the overall mold production efficiency); then spray the second, third, fourth , Five...layers, the thickness of the mold is determined by the user's own needs.

Note on operation of soft porcelain mold silicone:

①The silica gel the curing agent must be stirred evenly to avoid the phenomenon of non-curing of the silica gel;

②The configured liquid silica gel should be used up as much as possible within the operable time;

③When the original model is made of glass, ceramics coated with paint, the original model should be evenly coated with shampoo solution soapy water. After the water evaporates, refill brush the mold silica gel, which is beneficial to better demolding;

④Additional silica gel condensed silica gel cannot be in contact with each other, otherwise the silica gel will be "poisoned" the silica gel will be cured;

⑤Do contact with water, impurities, organotin catalysts, acids, alkalis, compounds containing nitrogen, phosphorus, sulfur during the operation of addition molding silica gel. These substances should be mixed during use to avoid the phenomenon of non-curing of silica gel.

Parameters of soft porcelain mold silicone:

color | White/Translucent | |||||

Hardness (Shaw A) | 15±2 | 20±2 | 25±2 | 30±2 | 33±2 | 40±2 |

Vulcanizing agent addition (%) | 2-3 | |||||

Dynamic adhesion (mPa. S) | 1.3w±0.2w | 1.7w±0.2w | 2.5w±0.2w | 2.7w±0.2w | 2.5w±0.2w | 1.5w±0.2w |

Tensile strength (MPa) | 2.5 | 2.8 | 3.4 | 4.0 | 3.5 | |

Tearing strength (KN/m) | 16±2 | 19±2 | 24±2 | 25±2 | 21±2 | |

Elongation (%) | 380 | 530 | 410 | 420 | 450 | 180 |

Density (g/cm) | 1.08 | 1.09 | ||||

Operation time (min) | 30-50 | 30-40 | 30-50 | |||

Curing time (H) | 4-5 | 3-4 | 4-5 | |||

Line shrinkage rate (%) | 0.3 | |||||

Conventional packing | 25kg | |||||

Note: The above parameters are only regular parameters. If you have special requirements, please contact our company; the hardness, viscosity, operating time after curing can be specially adjusted provided according to customer needs.

Contact: Manager Zhang 13823551369

Contact: Manager Zhang 13823551369

Manager Chen 13316540440

Mail box: 3265465343@qq.com

Mail box: 3265465343@qq.com

Fax: 0755-84826339

Fax: 0755-84826339

Address: 3020, Longcheng Avenue, Longgang District, Shenzhen, Guangdong Province

Address: 3020, Longcheng Avenue, Longgang District, Shenzhen, Guangdong Province

|  | |

| Hongtu Mobile Station | Ali shop |