Contact: Manager Zhang 13823551369

Manager Chen 13316540440

Mail box: 3265465343@qq.com

Fax: 0755-84826339

Website: www.szhtgj.cn

Address: 3020, Longcheng Avenue, Longgang District, Shenzhen, Guangdong Province

Introduction of tire mold silicone:

Tire mold silicone is a two-component vulcanized silicone rubber at room temperature, A-component silicone, B-component curing agent, tire mold silicone is divided into addition molding condensation type, the ratio of the former silicone curing agent is 1:1, the latter silicone The ratio of curing agent is 100:2-3. Taking into account the reasons of production cost, generally more customers adopt the condensation type.

Recommended tire mold silicone application hardness:

Tire silicone is professionally used in the production of overmoulding pouring moulds such as tire turning molds, tire aluminum mold casting, precision molds, etc. The recommended hardness range is 15-40 Shore degrees, the final hardness value is determined according to customer product requirements processes.

Features of tire mold silicone:

1. Easy to discharge bubbles, easy to demould, easy to infuse brush;

2. No low molecules are released during the cross-linking process, the shrinkage rate is small;

3. High tearing strength, good tensile force, the finished mold is deformed;

4. High temperature resistance, temperature resistance up to 260℃;

5. There are many times of turning over the mold, the silicone mold can be reused, the service life is longer.

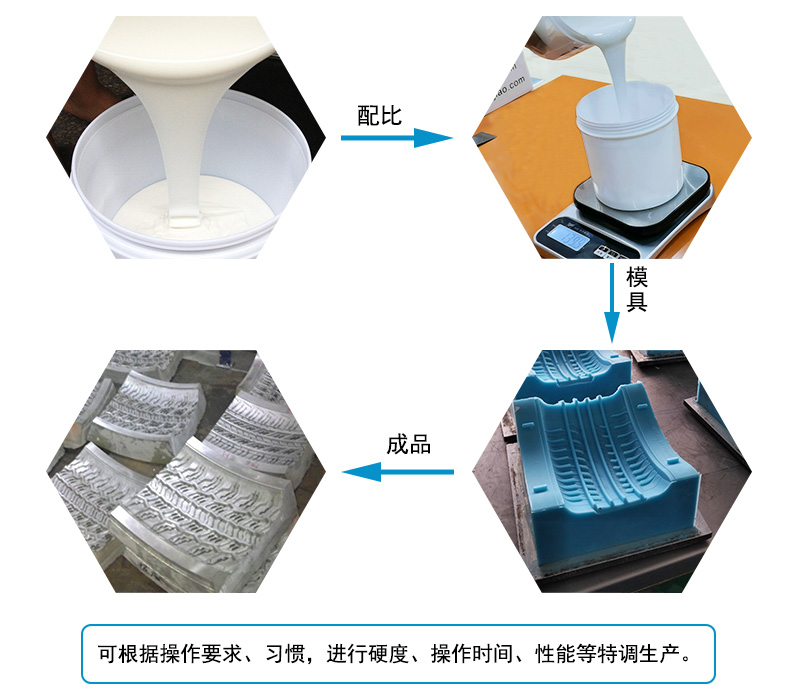

Tire mold silicone operation process:

1. Prepare tools: cardboard, ruler, knife, hot melt glue gun, etc.;

2. Treat the mold species, fix the mold species on the wooden board, apply a layer of release agent evenly;

3. Cut the corresponding cardboard to surround the mold, use hot melt glue to seal the gap of the cardboard, leave a distance of about 5mm between the cardboard the mold, apply a release agent;

4. According to the size of the product, weigh the silica gel according to the ratio of 100:2-3, mix stir evenly, then put it into a vacuum machine to vacuum (vacuum to -0.1mpa);

5. Pour the vacuumed tire mold silicone into the mold, wait for the silicone to fully cure, remove the silicone mold, trim the periphery of the silicone mold with scissors. At this point, the whole process is over, the finished silicone mold can be put into use after 24 hours.

Note on the operation of tire mold silicone:

1.要使用干净操作工具,以免硅胶混入杂质,影响固化;

2.固化剂的添加量应视温度而定,气温高则减少。固化剂若添加过量会影响模具质量,硅胶模具会变脆;固化剂添加少则会延长固化时间;

3.抽真空到-0.1mpa即可,抽真空时间不宜过长,防止硅胶在抽真空时发生交联反应,使硅胶变的一块一块的,造成原料浪费;

4.硅胶模具制作完成后,保存在通风、阴凉、干燥的地方,24小时后在投入生产。

Tyre mold silicone parameters:

color | White/Translucent | |||||||

Hardness (Shore A) | 15±2 | 20±2 | 25±2 | 30±2 | 33±2 | 40±2 | ||

Vulcanizing agent addition (%) | 2-3 | |||||||

Dynamic viscosity (mPa.s) | 1.3w±0.2w | 1.7w±0.2w | 2.5w±0.2w | 2.7w±0.2w | 2.5w±0.2w | 1.5w±0.2w | ||

Tensile strength (MPa) | 2.5 | 2.8 | 3.4 | 4.0 | 3.5 | |||

Tearing strength (KN/m) | 16±2 | 19±2 | 24±2 | 25±2 | 21±2 | |||

Elongation(%) | 380 | 530 | 410 | 420 | 450 | 180 | ||

Density (g/cm³) | 1.08 | 1.09 | ||||||

Operating time (min) | 30-50 | 30-40 | 30-50 | |||||

Curing time (h) | 4-5 | 3-4 | 4-5 | |||||

Linear shrinkage rate (%) | 0.3 | |||||||

standard packaging | 25kg | |||||||

Note: The above parameters are only regular parameters. If you have special requirements, please contact our company; the hardness, viscosity, operating time after curing can be specially adjusted provided according to customer needs.

Contact: Manager Zhang 13823551369

Contact: Manager Zhang 13823551369

Manager Chen 13316540440

Mail box: 3265465343@qq.com

Mail box: 3265465343@qq.com

Fax: 0755-84826339

Fax: 0755-84826339

Address: 3020, Longcheng Avenue, Longgang District, Shenzhen, Guangdong Province

Address: 3020, Longcheng Avenue, Longgang District, Shenzhen, Guangdong Province

|  | |

| Hongtu Mobile Station | Ali shop |