Contact: Manager Zhang 13823551369

Manager Chen 13316540440

Mail box: 3265465343@qq.com

Fax: 0755-84826339

Website: www.szhtgj.cn

Address: 3020, Longcheng Avenue, Longgang District, Shenzhen, Guangdong Province

Introduction of candle mold silicone:

Candle mold silicone is a kind of liquid silicone rubber, composed of AB two components, that is, component A is silica gel component B is curing agent. The product has two types: addition type condensation type. The addition type mold silicone is environmentally friendly silicone, the ratio between silicone curing agent is 1:1; the condensation type is industrial-grade silicone, the ratio between silicone curing agent is 100:2 100:2.5. Candle mold silica gel can be cured at room temperature heated to form.

Features of candle mold silicone:

1. Good fluidity, easy operation, easy demolding, many times of mold turning;

2. It has the advantages of burning resistance, corrosion resistance, tensile strength, good tear resistance;

3. It does emit oil solves the flame retardant problem of candle wick;

4. Addition molding silica gel is non-toxic, tasteless, safe environmentally friendly;

5. The color, hardness, viscosity, operating time of silica gel can be adjusted according to customer requirements.

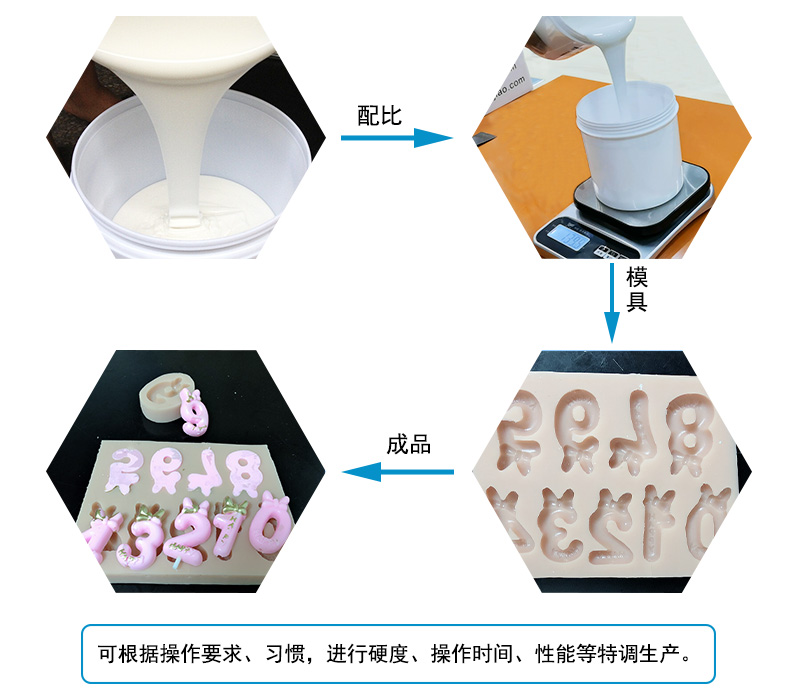

Candle mold silicone operation:

1. Mix the silicone curing agent according to a specific ratio stir evenly (1:1 for addition-type silicone; 100:2~2.5 for condensation-type silicone);

2. Put the mixed evenly mixed mold silicone into a vacuum machine for vacuuming exhausting bubbles (if there is no vacuuming machine, the curing time of the silicone can be prolonged, so that the bubbles are naturally eliminated, but this kind of bubble removal effect is Very ideal);

3. Spray (coat) the mold the mold frame that have been made with release agent, fix the mold in the middle, slowly pour the bubbled silica gel into the mold frame until the silica gel completely covers the mold, then static Just wait for it to solidify;

4. After the silicone is completely cured, demould, then process the edge burr, the silicone mold is completed.

Reminder: After the product is demolded, it is recommended to put it into production after being placed for 24 hours, which will help increase the number of mold turning times the service life of the silicone mold.

Caution for candle mold silicone operation:

1. In order to prevent changes in the physical properties of silica gel, it is recommended to add silicone oil;

2. The configured silica gel should be used up within the operating time to avoid waste of raw materials;

3. The silica gel curing agent must be stirred evenly to prevent the non-curing phenomenon of the silica gel due to uneven mixing;

4. The addition-molded silica gel should be in contact with any condensation type silica gel to prevent the "poisoning" of the silica gel causing the silica gel to cure;

5. Addition-molded silica gel should be in contact with water, impurities, organotin catalysts compounds containing nitrogen, phosphorus, sulfur, etc., these substances should be mixed in during use, otherwise silica gel will be "poisoned";

6. Smoking should be prohibited during operation.

Silicone candle mold uses:

Candle mold silicone is mainly used to make hand-made candle wax figures, DIY candle molds, Christmas candle molds, holiday candle molds, birthday wedding candle molds, jelly candle molds, handicraft candle molds, lighting candles various decoration handicraft molds. The recommended hardness range is 10-20 Shore degrees, the final hardness value is determined according to customer product requirements processes.

Candle mold silicone parameters:

color | White/Translucent | |||||

Hardness (Shore A) | 15±2 | 20±2 | 25±2 | 30±2 | 33±2 | 40±2 |

Vulcanizing agent addition (%) | 2-3 | |||||

Dynamic viscosity (mPa.s) | 1.3w±0.2w | 1.7w±0.2w | 2.5w±0.2w | 2.7w±0.2w | 2.5w±0.2w | 1.5w±0.2w |

Tensile strength (MPa) | 2.5 | 2.8 | 3.4 | 4.0 | 3.5 | |

Tearing strength (KN/m) | 16±2 | 19±2 | 24±2 | 25±2 | 21±2 | |

Elongation(%) | 380 | 530 | 410 | 420 | 450 | 180 |

Density (g/cm³) | 1.08 | 1.09 | ||||

Operating time (min) | 30-50 | 30-40 | 30-50 | |||

Curing time (h) | 4-5 | 3-4 | 4-5 | |||

Linear shrinkage rate (%) | 0.3 | |||||

standard packaging | 25kg | |||||

Note: The above parameters are only regular parameters. If you have special requirements, please contact our company; the hardness, viscosity, operating time after curing can be specially adjusted provided according to customer needs.

Contact: Manager Zhang 13823551369

Contact: Manager Zhang 13823551369

Manager Chen 13316540440

Mail box: 3265465343@qq.com

Mail box: 3265465343@qq.com

Fax: 0755-84826339

Fax: 0755-84826339

Address: 3020, Longcheng Avenue, Longgang District, Shenzhen, Guangdong Province

Address: 3020, Longcheng Avenue, Longgang District, Shenzhen, Guangdong Province

|  | |

| Hongtu Mobile Station | Ali shop |