Contact: Manager Zhang 13823551369

Manager Chen 13316540440

Mail box: 3265465343@qq.com

Fax: 0755-84826339

Website: www.szhtgj.cn

Address: 3020, Longcheng Avenue, Longgang District, Shenzhen, Guangdong Province

Introduction of addition molding high temperature resistant mold silicone:

Addition molding high temperature resistant mold silicone is a mold glue with special anti-burning agent introduced by our company. It is suitable for various high temperature resistant products. It is cured by platinum catalyst has passed FDA food-grade certification. Produced with high-quality raw materials at home abroad, the gum is fine without impurities!

Addition molding high temperature resistant mold silicone use:

Addition molding high temperature resistant mold silica gel can be used to make various precision parts, potting of various high temperature resistant electronic equipment, film mold making of various high temperature resistant products. It can also be used to make human wax figures, artificial robots, artificial human wax figures, adult products, food molds, cake molds, candy molds, artificial dishes, yacht gel coats, speedboat gel coats other products mold making.

Features of high temperature resistant mold silicone:

1. Add special anti-burning agent, silica gel is super high temperature resistant;

2. Food grade, non-toxic tasteless, safe environmentally friendly;

3. Good fluidity, fine gel, no impurities, no bubbles;

4. Easy demoulding, many times of mould turning, long service life of silicone mould.

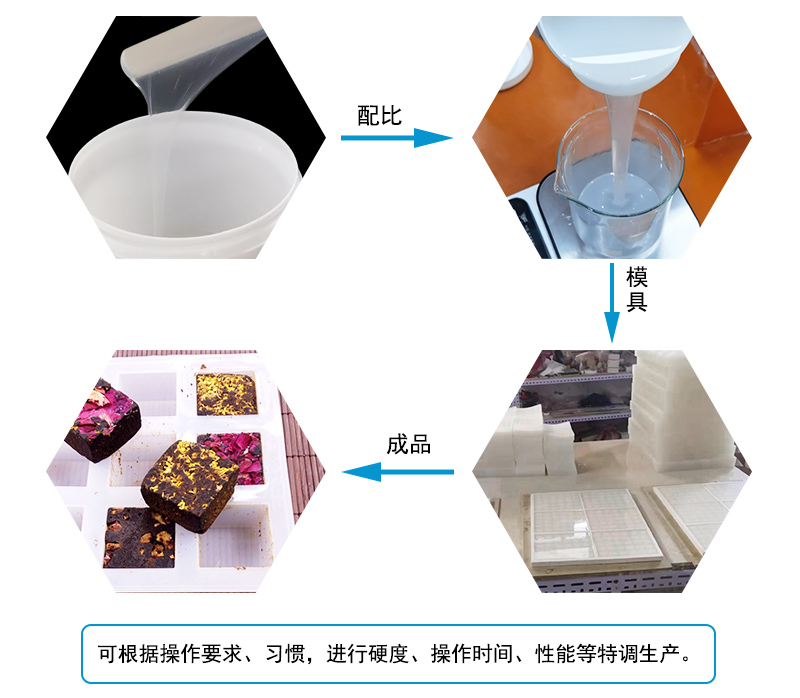

Add molding high temperature resistant mold silicone operation:

1. Mix the AB component in a ratio of 1:1 stir evenly (must be fully stirred evenly to avoid non-curing of the silica gel);

2. Put the stirred silica gel into a vacuum machine for vacuuming exhausting bubbles (the curing time can be prolonged if there is no vacuum machine, because it naturally eliminates bubbles, but this kind of bubble extraction effect is very ideal);

3. Slowly pour the addition-molded liquid silicone rubber that has drained bubbles into the product mold to be made, let the glue slowly flow into all corners of the mold, if necessary, perform a second infusion;

4. Keep the mold in a static state after the silica gel is poured, the mold can be demolded after it is completely cured.

Note on operation of adding molding high temperature resistant mold silicone:

1. Do contact with any other condensed silica gel during use, otherwise it will cause the silica gel to appear "poisoned" cause the silica gel to cure;

2. Do touch water, impurities, organotin catalysts, acids, alkalis other organic compounds containing nitrogen, phosphorus, sulfur, otherwise it will affect the curing of silica gel, these substances cannot be mixed during use;

3. Smoking is prohibited during operation to prevent "poisoning" of silica gel;

4. It should be stored in a dry environment.

Addition molding high temperature resistant mold silicone parameters:

Exterior | translucent | ||||

Hardness (Shore A) | 15±2 | 20±2 | 25±2 | 30±2 | 40±2 |

Mixing weight ratio of two components (A:B) | 1:1 | 1:1 | 1:1 | 1:1or10:1 | 1:1or10:1 |

Dynamic viscosity (mPa.s) | 6000±1000 | 8000±2000 | 8000±2000 | 9000±2000 | 12000±2000 |

Tensile strength (MPa) | 4.2 | 4.7 | 5.2 | 5.2 | 6.2 |

Tear strength (kN/m) | 12±2 | 14±2 | 13±2 | 12±2 | 12±2 |

Elongation(%) | 470 | 520 | 470 | 470 | 320 |

Density (g/cm³) | 1.05 | 1.05 | 1.07 | 1.13 | 1.14 |

Operating time (min) | 20-40 | ||||

Curing time (h) | 3-5h(25℃) 20-30min(60℃) | ||||

Line shrinkage rate (%) | ≤0.1% | ||||

standard packaging | AB glue 25kg/barrel each | ||||

Note: The above parameters are only regular parameters. If you have special requirements, please contact our company; the hardness, viscosity, operating time after curing can be specially adjusted provided according to customer needs.

Contact: Manager Zhang 13823551369

Contact: Manager Zhang 13823551369

Manager Chen 13316540440

Mail box: 3265465343@qq.com

Mail box: 3265465343@qq.com

Fax: 0755-84826339

Fax: 0755-84826339

Address: 3020, Longcheng Avenue, Longgang District, Shenzhen, Guangdong Province

Address: 3020, Longcheng Avenue, Longgang District, Shenzhen, Guangdong Province

|  | |

| Hongtu Mobile Station | Ali shop |