Contact: Manager Zhang 13823551369

Manager Chen 13316540440

Mail box: 3265465343@qq.com

Fax: 0755-84826339

Website: www.szhtgj.cn

Address: 3020, Longcheng Avenue, Longgang District, Shenzhen, Guangdong Province

Introduction of Addition Mold Silicone:

Addition mold silicone rubber is one of the higher-grade mold rubbers, with simple operation process low cost! It is formed by curing with platinum catalyst, can be cured at room temperature heated. No by-products are produced during the vulcanization process, the shrinkage rate is small, deep vulcanization is possible.

Addition mold silicone rubber use:

Addition mold silicone rubber can be used in food molds, various precision parts silicone molds that require high temperature products. It can be used in aerospace parts, auto parts, military supplies, robotic silicone molds, glass fiber reinforced plastics, ships, etc., can also be used It is used in the production of human wax figures, artificial robots, artificial human wax figures, adult products other products.

Features of addition mold silicone rubber:

1. Small molecular weight, low viscosity, convenient processing forming;

2. Comply with FDA food grade certification, non-toxic tasteless, safe environmentally friendly;

3. Good tensile force, high temperature resistance, tear resistance yellow deformation resistance;

4. Has excellent thermal stability heat resistance;

5. Performance can be adjusted according to customer needs.

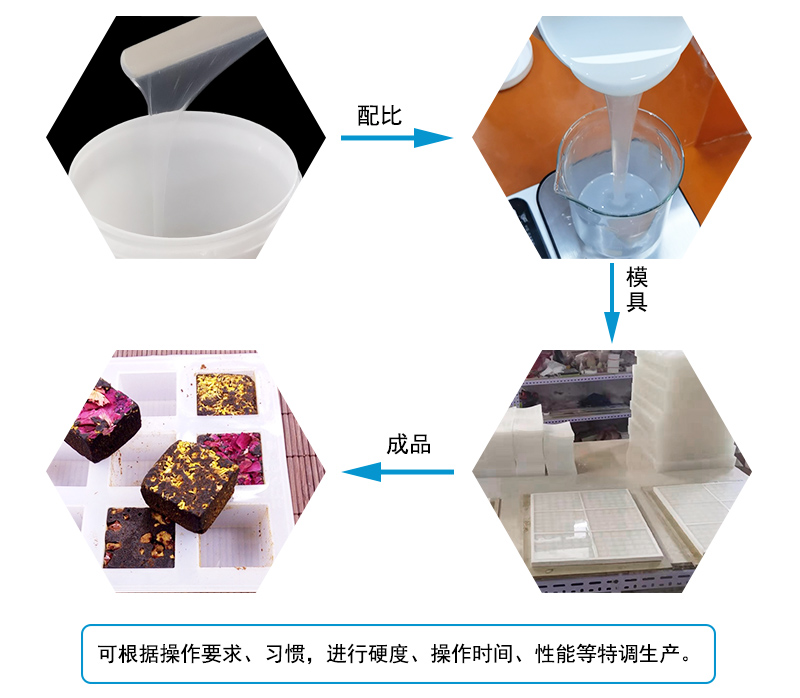

Adding mold silicone rubber operation:

1. Mix the AB component in a ratio of 1:1 stir evenly (must be fully stirred evenly to avoid non-curing of the silica gel);

2. Put the stirred silica gel into a vacuum machine for vacuuming exhausting bubbles (the curing time can be prolonged if there is no vacuum machine, because it naturally eliminates bubbles, but this kind of bubble extraction effect is very ideal);

3. Slowly pour the addition-molded liquid silicone rubber that has drained bubbles into the product mold to be made, let the glue slowly flow into all corners of the mold, if necessary, perform a second infusion;

4. Keep the mold in a static state after the silica gel is poured, the mold can be demolded after it is completely cured.

Cautions on the operation of adding mold silicone rubber:

1. Prevent the addition of silica gel coming in contact with heavy metals such as nitrogen, phosphorus, sulfur, tin, cadmium, mercury. Addition molding silica gel is a medical-grade silica gel that is sticky, uncured, incompletely cured when it comes in contact with substances containing heavy metals during use.

2. During operation, it should be separated the container that has used condensed liquid silica gel. You can do a skin test on the mold before use to see if it will solidify before putting it into use.

Contact: Manager Zhang 13823551369

Contact: Manager Zhang 13823551369

Manager Chen 13316540440

Mail box: 3265465343@qq.com

Mail box: 3265465343@qq.com

Fax: 0755-84826339

Fax: 0755-84826339

Address: 3020, Longcheng Avenue, Longgang District, Shenzhen, Guangdong Province

Address: 3020, Longcheng Avenue, Longgang District, Shenzhen, Guangdong Province

|  | |

| Hongtu Mobile Station | Ali shop |