Contact: Manager Zhang 13823551369

Manager Chen 13316540440

Mail box: 3265465343@qq.com

Fax: 0755-84826339

Website: www.szhtgj.cn

Address: 3020, Longcheng Avenue, Longgang District, Shenzhen, Guangdong Province

Introduction of craft mold silicone:

Handicraft mold silicone is a kind of mold liquid silicone specially developed for turning over mold crafts. It is composed of AB component, A component silica gel, B component curing agent. When using, the two components are mixed stirred in a certain weight ratio It can be cured at room temperature evenly. The ratio of addition-type silica gel is 1:1, the ratio of condensation type silica gel is 100:2-2.5.

Uses of handicraft mold silicone:

Handicraft mold silicone is mainly used for toys, craft gifts, products with fine patterns, overmolds, infusion mold products, POLI crafts, resin crafts, lighting, candles, other crafts precision mold manufacturing.

Features of handicraft mold silicone:

①Good fluidity, low viscosity, good operability;

②High low temperature resistance, acid alkali resistance, aging resistance;

③Good tensile force, good tear resistance, the made silicone mold will deform;

④Low linear shrinkage, easy demolding, many times of mold turning;

⑤Color, hardness, viscosity operating time can be adjusted as required.

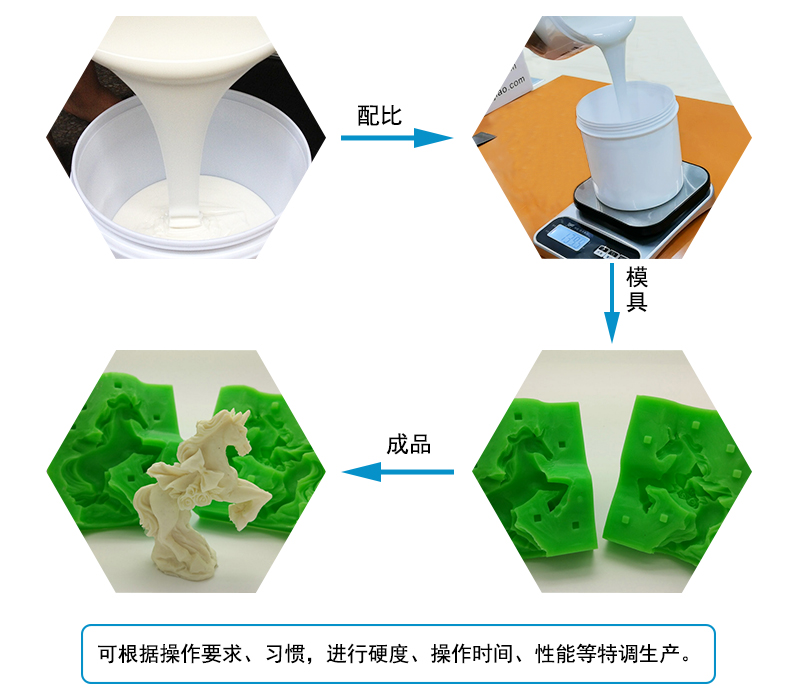

Handicraft mold silicone operation:

①Mix the silica gel curing agent according to the weight ratio, mix stir evenly (addition ratio 1:1, condensation type ratio 100:2-2.5);

②Put the well-mixed silica gel into a vacuum machine for vacuuming de-bubbling treatment. The advantage of this is to make the finished product smooth bubble-free. (If there is no vacuum machine, the curing time can be extended the bubbles can be discharged naturally, but the effect is very satisfactory);

③Spray (paint) a layer of release agent on the already made mold mold frame, fix the mold in the middle, pour the bubbled liquid silicone slowly steadily into the mold frame until the silicone is completely covered Hold the mold species, then wait for it to completely solidify;

④After the mold silicone is completely cured, the mold can be demolded, the silicone mold is taken out for edge treatment.

⑤Generally, the silicone mold is recommended to be put into use after being placed for 24 hours, so that the good use effect of the mold can be exerted.

Handicraft mold silicone operation attention:

①The silica gel the curing agent must be stirred evenly to avoid the phenomenon of non-curing of the silica gel;

②The configured liquid silica gel should be used up as much as possible within the operable time;

③When the original model is made of glass, ceramics coated with paint, the original model should be evenly coated with shampoo solution soapy water. After the water evaporates, refill brush the mold silica gel, which is beneficial to better demolding;

④Additional silica gel condensed silica gel cannot be in contact with each other, otherwise the silica gel will be "poisoned" the silica gel will be cured;

⑤Do contact with water, impurities, organotin catalysts, acids, alkalis, compounds containing nitrogen, phosphorus, sulfur during the operation of addition molding silica gel. These substances should be mixed during use to avoid the phenomenon of non-curing of silica gel.

Handicraft mold silicone parameters:

color | White/Translucent | |||||

Hardness (Shore A) | 15±2 | 20±2 | 25±2 | 30±2 | 33±2 | 40±2 |

Vulcanizing agent addition (%) | 2-3 | |||||

Dynamic viscosity (mPa.s) | 1.3w±0.2w | 1.7w±0.2w | 2.5w±0.2w | 2.7w±0.2w | 2.5w±0.2w | 1.5w±0.2w |

Tensile strength (MPa) | 2.5 | 2.8 | 3.4 | 4.0 | 3.5 | |

Tearing strength (KN/m) | 16±2 | 19±2 | 24±2 | 25±2 | 21±2 | |

Elongation(%) | 380 | 530 | 410 | 420 | 450 | 180 |

Density (g/cm³) | 1.08 | 1.09 | ||||

Operating time (min) | 30-50 | 30-40 | 30-50 | |||

Curing time (h) | 4-5 | 3-4 | 4-5 | |||

Linear shrinkage rate (%) | 0.3 | |||||

standard packaging | 25kg | |||||

Note: The above parameters are only regular parameters. If you have special requirements, please contact our company; the hardness, viscosity, operating time after curing can be specially adjusted provided according to customer needs.

Contact: Manager Zhang 13823551369

Contact: Manager Zhang 13823551369

Manager Chen 13316540440

Mail box: 3265465343@qq.com

Mail box: 3265465343@qq.com

Fax: 0755-84826339

Fax: 0755-84826339

Address: 3020, Longcheng Avenue, Longgang District, Shenzhen, Guangdong Province

Address: 3020, Longcheng Avenue, Longgang District, Shenzhen, Guangdong Province

|  | |

| Hongtu Mobile Station | Ali shop |