Contact: Manager Zhang 13823551369

Manager Chen 13316540440

Mail box: 3265465343@qq.com

Fax: 0755-84826339

Website: www.szhtgj.cn

Address: 3020, Longcheng Avenue, Longgang District, Shenzhen, Guangdong Province

Introduction of high transparent mold silicone:

Highly transparent mold silicone is a kind of two-component addition molding silicone, but its transparency is quite high. The same product has the advantages of high transparency good mold release. It can be seen whether the casting material in the mold has defects such as bubbles.

High transparent mold silicone use:

It is used in the production of diamond molds such as imitation zircon, imitation gemstones, resin diamonds, crystal face drills, simulation drills, etc. It can also be used for model manufacturing of precision automobiles, models, mechanical parts, nail (nail small jewelry) molds, etc., can also be applied Manufacturing of mold making in furniture industry electronics industry.

Features of high transparent mold silicone:

1. This product is a two-component addition molding liquid silicone rubber, the ratio is 1:1

2. It is limited by the thickness of the product can be deeply cured

3. Has excellent high temperature resistance, the temperature can reach 300-500 degrees

4. Food grade, non-toxic tasteless, passed FDA food grade certification

5. High tensile tear resistance, many times of mold turning

6. It can be heated cured, easy to form, easy to operate

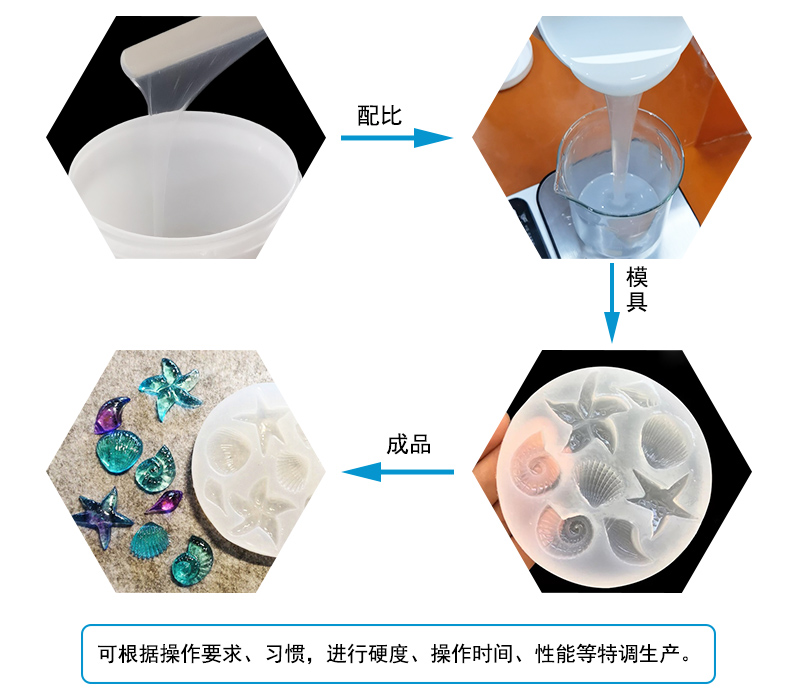

High transparent mold silicone operation process:

1. Mixing: A component (base rubber) B component (curing agent) are mixed at a weight ratio of 1:1. The mixing can be done manually with equipment.

2. Defoaming: The mixed rubber should be defoamed before filling. When used in a small amount, it can be carried out in a vacuum dryer. Under vacuum, the volume of the rubber will foam increase by 4 to 5 times. Therefore, the volume of the degassing container should be 4 to 5 times larger than the volume of the rubber. After a few minutes The volume of the glue returns to normal, the defoaming process is completed when no bubbles escape on the surface (about 10 minutes).

3. Surface treatment: the surface of the mold the surface of the material that needs to be potted should be cleaned then liquid paraffin should be used as a release agent.

4. Vulcanization demoulding: the compound after mixing deaeration is cured at 120±5℃ for 30 minutes, 60~70℃ for 2~3 hours, curing time at room temperature is 24 hours, curing temperature time can be based on Depending on process conditions.

Packing, storage precautions:

1. The base glue of this product is packaged in 40kg/group 400kg/group.

2. This product is non-hazardous should be sealed stored in a cool place to prevent rain sunlight.

3. The storage period of this product is half a year. If the viscosity increases during storage, its fluidity can be restored under the action of shearing force (stirring). It is recommended to put the rubber compound in the container mix it first, then add the curing agent to mix. It can still be used after the overdue re-inspection is qualified.

4. Avoid contact with condensed silicone rubber vulcanizing agent during operation. Amines, sulfur, phosphorus other chemicals may cause the rubber to vulcanize.

High transparent mold silicone parameters:

Appearance (Part A) | Colorless transparent liquid |

A, B component ratio | 1:1 |

AB mixed viscosity CPS | 39000 |

Operation time (25℃) min | 45 |

Vulcanization conditions (℃/h) | 25℃/4-6 80℃/0.5h~1h |

Density/ g·cm-3 | 1.1 |

Hardness (JIS A) | 20 |

Elongation at break/% | ≥210 |

Tear strength/ KN·m-1 | ≥15.4 |

Tensile strength/Mpa | ≥2.5 |

Linear shrinkage/% | 0.1 |

Contact: Manager Zhang 13823551369

Contact: Manager Zhang 13823551369

Manager Chen 13316540440

Mail box: 3265465343@qq.com

Mail box: 3265465343@qq.com

Fax: 0755-84826339

Fax: 0755-84826339

Address: 3020, Longcheng Avenue, Longgang District, Shenzhen, Guangdong Province

Address: 3020, Longcheng Avenue, Longgang District, Shenzhen, Guangdong Province

|  | |

| Hongtu Mobile Station | Ali shop |