Contact: Manager Zhang 13823551369

Manager Chen 13316540440

Mail box: 3265465343@qq.com

Fax: 0755-84826339

Website: www.szhtgj.cn

Address: 3020, Longcheng Avenue, Longgang District, Shenzhen, Guangdong Province

Introduction of translucent mold silicone:

Semi-transparent mold silicone is a two-component environmentally friendly silicone, composed of two components A B, which can be cured at room temperature heated to form. Good fluidity, can be poured painted, easy to operate.

Translucent mold silicone use:

Semi-transparent mold silicone is mainly used in the production of silicone molds for precision products such as resin crafts, crafts models, carved Buddha statues, car models, military supplies, gift models, metal crafts, alloy vehicles, food silicone molds for cakes chocolates.

Features of translucent mold silicone:

1. Passed FDA food grade environmental protection certification, non-toxic tasteless;

2. Good liquidity, simple convenient operation;

3. It is limited by the thickness of the product, it can be cured deeply, can be cured at room temperature heated;

4. Shrinkage rate ≤0.1%, with dimensional stability, low molecules are released during the cross-linking process, so the volume remains unchanged, the made silicone mold does deform;

5. Low viscosity, can be poured painted, performance can be adjusted according to customer needs.

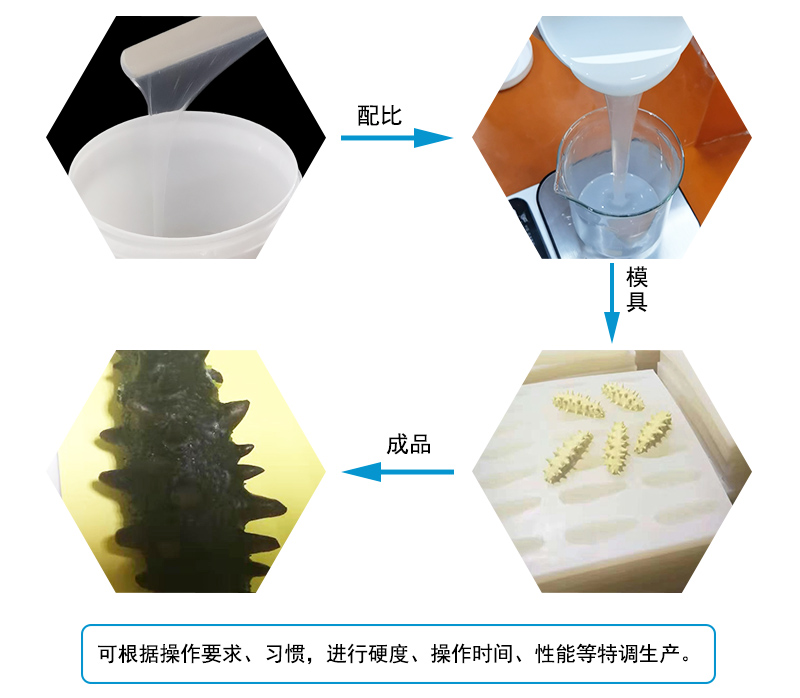

Translucent mold silicone operation:

1. Preparation of materials tools: rulers, knives, brushes, cardboard, etc.;

2. Deal with the mold species, fill the bottom of the mold species with sludge, make a tenon, which is a good mold species. The tenon release is about one centimeter away the mold, the mold release agent (clean water soapy water) is brushed around the mold;

3. According to the product structure, pattern purpose, the appropriate hardness of silica gel, mix stir evenly according to the ratio of 1:1, put it into the vacuum machine to vacuum to -0.01mpa, which makes the finished product smoother No bubbles;

4. Apply the vacuumed silica gel evenly on the mold. The thickness of the first layer of silica gel is less than 1mm, as long as it can cover the mold. After the first layer of silica gel is cured, apply the second layer of silica gel. The thickness of the layer of silica gel is thicker than that of the first layer;

5. When the second layer of silica gel is flowing, paste a layer of gauze on the silica gel to enhance the tear resistance of the silica gel. After trimming the gauze, apply a layer of silica gel evenly;

6. After the silicone is cured, trim the periphery neatly, separate the mold line according to the structure of the mold type, pile up the sludge below the mold line (the hardness of the sludge should be too large), trim the sludge neatly tightly. Model species. Make a tenon on the sludge to facilitate mold clamping;

7. Use a wooden board to fix the mold to make a plaster outer mold, pour the prepared plaster on the mold to repair the surroundings. After the plaster is solidified, remove the sludge, clean the plaster surface, repeat the above steps to make the other half of the plaster outer mold;

8. After the plaster is cured, remove the plaster outer mold, fix the plaster outer mold to make the mold back cover;

9. Clean the bottom of the mold, brush with release agent, wrap tape around the mold to prevent silicone overflowing. Add the adjusted silica gel to make the mold back cover, remove the silica gel back cover after the silica gel is cured;

10. Remove the plaster outer mold turn out the mold. The mold is now completed can be put into production after being placed for 24 hours.

Attention to translucent mold silicone operation:

1. Prevent the addition of silica gel coming in contact with heavy metals such as nitrogen, phosphorus, sulfur, tin, cadmium, mercury. Addition molding silica gel is a medical-grade silica gel that is sticky, uncured, incompletely cured when it comes in contact with substances containing heavy metals during use.

2. During operation, it should be separated the container that has used condensed liquid silica gel. You can do a skin test on the mold before use to see if it will solidify before putting it into use.

Contact: Manager Zhang 13823551369

Contact: Manager Zhang 13823551369

Manager Chen 13316540440

Mail box: 3265465343@qq.com

Mail box: 3265465343@qq.com

Fax: 0755-84826339

Fax: 0755-84826339

Address: 3020, Longcheng Avenue, Longgang District, Shenzhen, Guangdong Province

Address: 3020, Longcheng Avenue, Longgang District, Shenzhen, Guangdong Province

|  | |

| Hongtu Mobile Station | Ali shop |