Contact: Manager Zhang 13823551369

Manager Chen 13316540440

Mail box: 3265465343@qq.com

Fax: 0755-84826339

Website: www.szhtgj.cn

Address: 3020, Longcheng Avenue, Longgang District, Shenzhen, Guangdong Province

Introduction of injection mold silicone rubber:

Injection mold silicone is suitable for injection molding process. It is a two-component, highly transparent, high tear strength liquid silicone rubber. It is called injection silicone, injection rubber, injection silicone rubber, AB glue. It is produced vinyl monomers added with silica other additives, various liquid silicone molds are injected with an injection molding machine.

Silicone rubber injection mold uses:

Injection mold silicone rubber is used to replicate the molds of resin diamonds, crystal diamonds, zircons other jewelry. It is a transparent mold silicone for the production mass production of silicone molds for jewelry, ring diamonds other products. It is also suitable for precision casting prototype casting of auto parts, aircraft transmission parts other products.

Features of injection mold silicone rubber:

1. Thermal stability weather resistance, yellowing resistance, heat aging resistance;

2. Excellent transparency, high temperature resistance, excellent tear strength;

3. High temperature resistance, this silicone mold will cause damage when the resin drill is cured;

4. It belongs to food grade silica gel, has FDA food grade certification, is environmentally friendly, non-toxic tasteless.

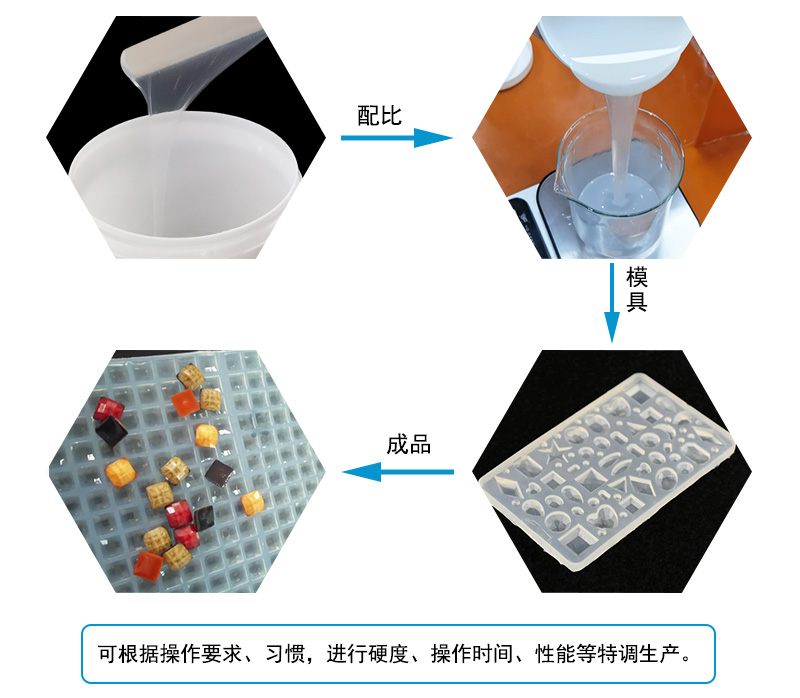

Injection mold silicone operation:

Injection mold silicone rubber is a two-component liquid silicone material, divided into A component B component. The work of the mixer (injection molding machine) will make the A component B component in an accurate ratio of 1:1. Mixed operation. In addition, due to product design requirements, there will be a color pump color metering part operation. After the injection machine is hydraulically extruded through the A B pipes, it is merged into a pipe AB mixed uniformly before injection.

Parameters of injection mold silicone rubber:

Appearance (Part A) | Colorless transparent liquid |

A, B component ratio | 10:1 |

A component viscosity CPS | 120000-140000 |

Operation time (25℃) | ≥4 hours |

Density g·cm-3 | 1.05 |

Hardness (JIS A) | 35 |

Elongation at break% | ≥350 |

Tear strength KN/m | ≥22 |

Tensile strength mpa.s | ≥5 |

Linear shrinkage% | 0.1 |

standard packaging | Common packaging with A B ratio of 10:1: 22KG/set (A component 20kg+B component 2kg) 220KG/set (A component 200kg+B component 20kg) |

Note: The above parameters are only regular parameters. If you have special requirements, please contact our company; the hardness, viscosity, operating time after curing can be specially adjusted provided according to customer needs.

Contact: Manager Zhang 13823551369

Contact: Manager Zhang 13823551369

Manager Chen 13316540440

Mail box: 3265465343@qq.com

Mail box: 3265465343@qq.com

Fax: 0755-84826339

Fax: 0755-84826339

Address: 3020, Longcheng Avenue, Longgang District, Shenzhen, Guangdong Province

Address: 3020, Longcheng Avenue, Longgang District, Shenzhen, Guangdong Province

|  | |

| Hongtu Mobile Station | Ali shop |