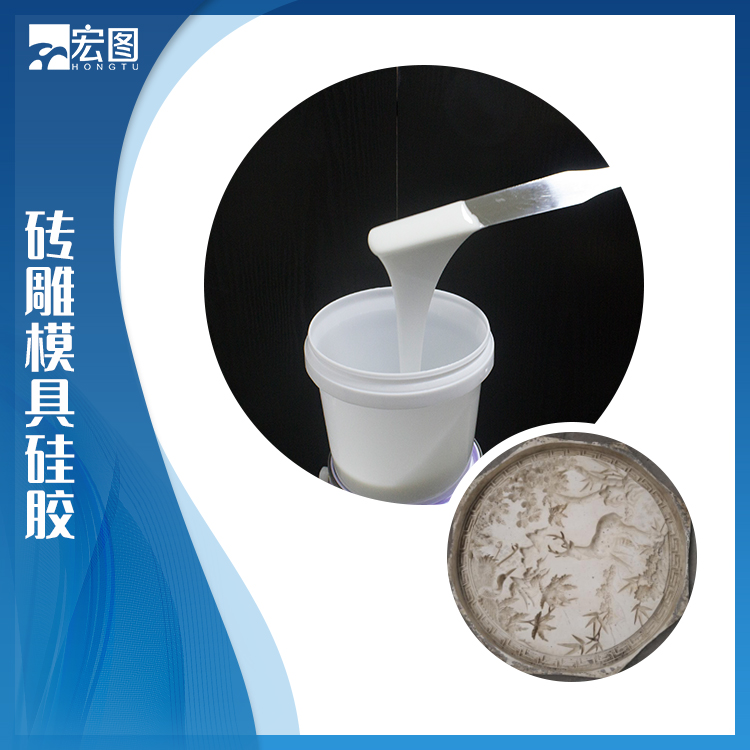

Brick carving mold silicone

Commodity Details

Introduction of brick carving mold silica gel:

Brick carving mold silicone is a mold glue made with a special anti-burning agent. The made silicone mold is more resistant to burning. It is produced with high-quality raw materials at home abroad, without impurities, has better product performance.

Silicone for brick carving mold:

Brick carving mold silica gel is suitable for the production of various brick carving molds product duplication. It can also be used in the duplication mold making of cultural stones, cement products, sandstone reliefs, cultural bricks, grc components, plaster lines other industries. The recommended hardness range is 15-40 Shore degrees, the final hardness value is determined according to customer product requirements processes.

Features of brick carving mold silicone:

1. Good fluidity, simple operation, no sticking, easy demoulding, no damage to the mold;

2. Special anti-burning agent is added to the silicone to make the silicone mold more resistant to burning;

3. There are many times of mold turning, good copy effect, long service life of silicone mold, more cost-saving than ordinary silicone;

4. Excellent performance, can be adjusted according to customer requirements.

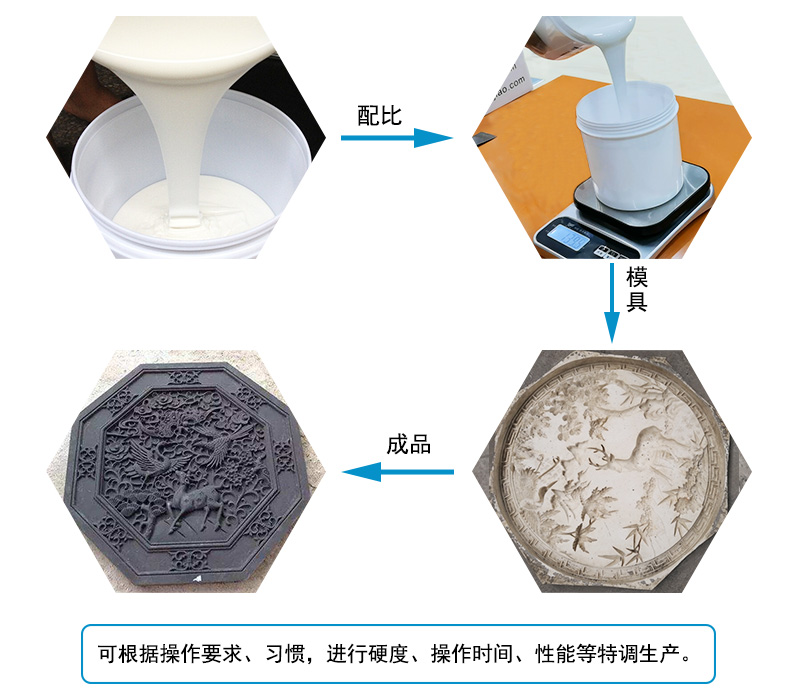

Brick carving mold silicone operation:

1. Stir the silicone curing agent according to the ratio of 100:2-3;

2. After the silica gel the curing agent are evenly stirred, perform vacuuming to remove bubbles. The vacuuming time should be too long, under normal circumstances, it should exceed ten minutes;

3. Grind polish the mold to be smooth, then apply the release agent. The release agent must be evenly applied, the mold must be fixed on the wooden board with glue;

4. Pour the vacuumed silica gel directly onto the product. After the silica gel is dried formed, take out the product the mold is formed.

Note on the operation of brick carving mold silica gel:

1. Use clean operating tools to prevent silica gel mixing with impurities affecting curing;

2. The silica gel the curing agent must be stirred evenly. If they are evenly stirred, the silica gel will be unevenly dried cured, which will affect the service life of the silicone mold the number of mold overturns, even cause the mold to be scrapped.

3. The vacuuming time should be too long. Under normal circumstances, it should exceed ten minutes. If the vacuuming time is too long, the silica gel will solidify immediately, resulting in a cross-linking reaction, making the silica gel piece by piece unable to be painted poured. This wastes silica gel;

4. The perfusion mold is generally made of silicone with relatively soft hardness, so that it is easier to demold will damage the products in the silicone mold;

5. The product model to be copied before pouring the silica gel must be filled with a release agent release agent.

Parameters of brick carving mold silica gel:

color | white/translucent | |||||

Hardness (Shore A) | 15±2 | 20±2 | 25±2 | 30±2 | 33±2 | 40±2 |

Vulcanizing agent addition (%) | 2-3 | |||||

Dynamic viscosity (mPa.s) | 1.3w±0.2w | 1.7w±0.2w | 2.5w±0.2w | 2.7w±0.2w | 2.5w±0.2w | 1.5w±0.2w |

Tensile strength (MPa) | 2.5 | 2.8 | 3.4 | 4.0 | 3.5 | |

Tearing strength (KN/m) | 16±2 | 19±2 | 24±2 | 25±2 | 21±2 | |

Elongation(%) | 380 | 530 | 410 | 420 | 450 | 180 |

Density (g/cm³) | 1.08 | 1.09 | ||||

Operating time (min) | 30-50 | 30-40 | 30-50 | |||

Curing time (h) | 4-5 | 3-4 | 4-5 | |||

Linear shrinkage rate (%) | 0.3 | |||||

standard packaging | 25kg | |||||

Note: The above parameters are only regular parameters. If you have special requirements, please contact our company; the hardness, viscosity, operating time after curing can be specially adjusted provided according to customer needs.

Recommended hardness of liquid mold silicone

hardness | 0 degrees-below 0 degrees | 5 degrees | 10 degrees - 20 degrees | 25 degrees - 35 degrees | 40 degree | 45 degrees -60 degrees |

Usage suggestion | It is super soft below 0 degrees, generally used for silicone doll adult products, sex products, etc. 0 degrees is slightly harder depending on customer needs. | 5 degree softness is generally used for making silicone products, but also for small surprising fondant molds, soap molds, pad printing rubber heads, etc. | 10°-20°C is suitable for all kinds of moulding products, with good softness good tear resistance, suitable for candles, handmade soaps, handicrafts, chocolate candies, special-shaped plaster threads, etc. | Good tear resistance, high hardness, no deformation, suitable for split brush molds. Such as cement products, cultural stones, sandstone reliefs, resin crafts, tire molds, etc. | 40 degrees is very hard, similar to the hardness of sports shoe soles, suitable for filling, such as electronic potting, it is recommended to open molds. | When the hardness of silica gel is higher than 50 degrees, it is easy to become brittle, the tear resistance performance is reduced, it has no flexibility. It is suitable for filling is recommended for use in mold opening. |