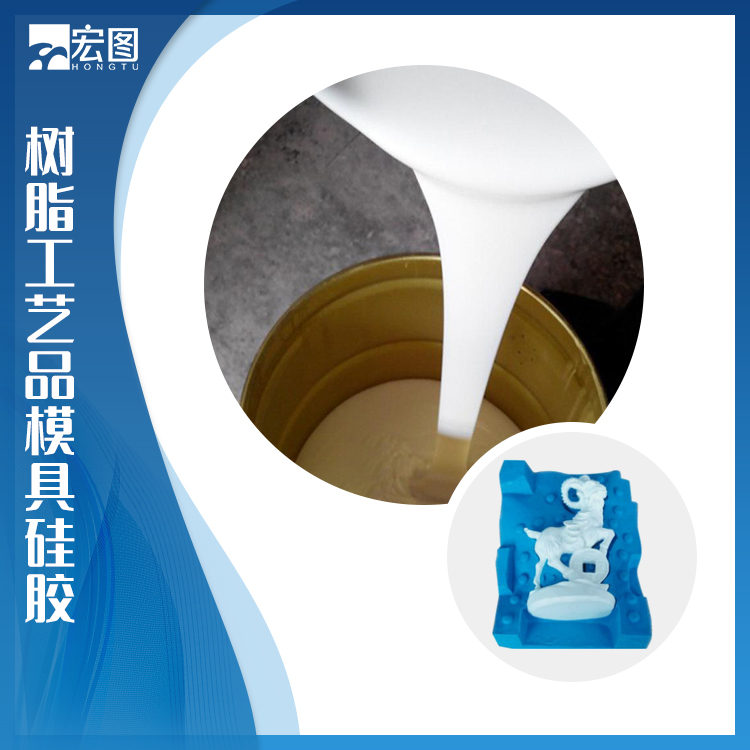

Resin crafts mold silicone

Commodity Details

Introduction of Resin Craft Mold Silicone:

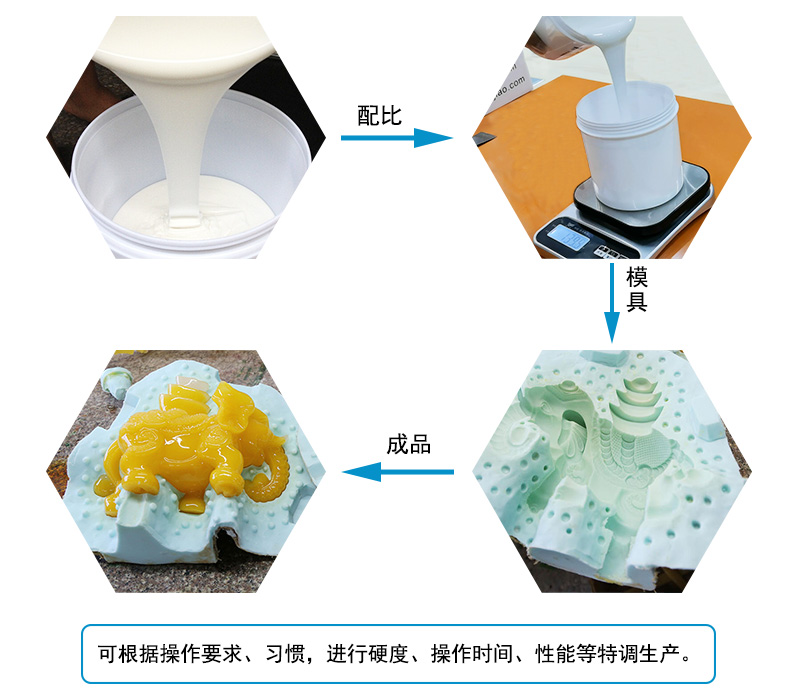

Resin handicraft mold silicone is a special condensation mold silicone rubber for resin handicrafts, composed of component A component B, A: silica gel. B: Curing agent. When in use, the two components of AB are mixed stirred evenly according to the weight ratio of 100:1.5 100:2. That is, 100 grams of silica gel 1.5 grams 2 grams of curing agent are mixed stirred evenly. Simple operation fast forming! Resin handicraft mold silicone is a good raw material for the manufacture of over-molded resin handicraft silicone mold!

Resin handicraft mold silicone use:

Resin crafts mold silicone is suitable for making silicone molds of various crafts, such as glass resin, epoxy resin, Pu resin, etc. Whether it is a large complex piece a small piece with fine patterns, it can be replicated well. The recommended hardness range is 20-35 Shore degrees, which is determined according to customer product requirements the hardness value of the process.

Features of Resin Craft Mold Silicone:

① This product can withstand high temperature 180℃-300℃, if special burn-resistant materials are added, high temperature resistance will be higher;

② Shrinkage rate <1‰;

③ Good properties such as tensile strength tear resistance;

④ The made mold has many times of re-molding has a long service life, which is more cost-effective than ordinary silica gel;

⑤ The product hardness, curing time color can be adjusted according to customer needs.

Resin handicraft mold silicone operation:

1.将模具胶与固化剂按重量比100:2~3进行配比混合搅拌均匀;

2.将混合搅拌均匀后的硅胶放入抽真空机进行抽真空排气泡处理,这样做的好处就是让做出来的产品光滑无气泡(没有真空机的可以延长固化时间,让气泡自然排出,但效果不是很理想);

3.在已经制作好的模种及模框上喷(涂)上一层脱模剂,将模种固定在中间,把排完气泡的液体硅胶缓慢平稳的倒入模框内,直至硅胶完全覆盖住模种,然后静止等其完全固化;

4.等到模具硅胶完全固化后即可进行脱模,取出硅胶模具进行边缘处理;

5.一般硅胶模具做好建议放置24小时后在进行投入使用,可发挥出模具的好的使用效果。

Resin handicraft mold silicone operation attention:

1. It is recommended to add silicone oil during the operation. If you have to add it, please consult your supplier for the proportion of addition. Do add it yourself, which may cause the performance of silicone to decrease;

2. The proportioned silica gel should be used up within the operating time as soon as possible to avoid waste of raw materials;

3. The silica gel curing agent must be mixed evenly to prevent the phenomenon that the silica gel does cure;

4. This product belongs to condensation mold silicone, cannot be mixed with addition molding silicone.

Resin handicraft mold silicone parameters:

color | White/Translucent | |||||

Hardness (Shore A) | 15±2 | 20±2 | 25±2 | 30±2 | 33±2 | 40±2 |

Vulcanizing agent added(%) | 2-3 | |||||

Dynamic viscosity (mPa.s) | 1.3w±0.2w | 1.7w±0.2w | 2.5w±0.2w | 2.7w±0.2w | 2.5w±0.2w | 1.5w±0.2w |

Tensile strength (MPa) | 2.5 | 2.8 | 3.4 | 4.0 | 3.5 | |

Tearing strength (KN/m) | 16±2 | 19±2 | 24±2 | 25±2 | 21±2 | |

Elongation(%) | 380 | 530 | 410 | 420 | 450 | 180 |

Density (g/cm³) | 1.08 | 1.09 | ||||

Operating time (min) | 30-50 | 30-40 | 30-50 | |||

Curing time (h) | 4-5 | 3-4 | 4-5 | |||

Linear shrinkage rate (%) | 0.3 | |||||

standard packaging | 25kg | |||||

Note: The above parameters are only regular parameters. If you have special requirements, please contact our company; the hardness, viscosity, operating time after curing can be specially adjusted provided according to customer needs.