Plaster line mold silicone

Commodity Details

Introduction of Plaster Line Mold Silicone:

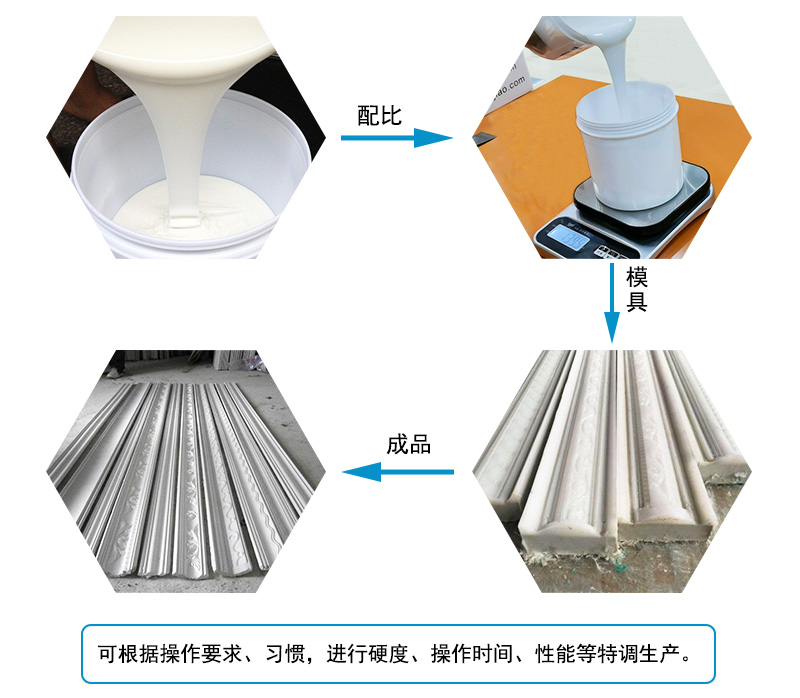

Generally, the plaster line mold silica gel used by customers to make silicone molds is mostly condensation mold silica gel. A few customers like to use addition mold silica gel. Plaster line mold silica gel is divided into AB two components, A component silica gel, B component curing agent. After mixing the silicone curing agent, it can be formed.

Uses of plaster line mold silicone:

Plaster line mold silica gel is suitable for all kinds of large, medium small pieces of plaster crafts, plaster decorative building materials, copying of building decoration technology the production of silicone molds. The recommended hardness range is 15-35 Shore degrees, the final hardness value is determined according to customer product requirements processes.

Features of plaster line mold silicone:

1. Good fluidity, easy operation, easy demoulding;

2. The mould made is deformed has the advantages of high temperature resistance, corrosion resistance, acid alkali resistance;

3. High tear strength, good tensile force, the mold can be reused, the number of mold reversals is large;

4. Low shrinkage rate (≤0.3%), fast curing forming at room temperature, performance can be adjusted according to customer requirements.

Plaster line mold silicone operation:

1. Prepare tools: knives, rulers, brushes, scissors, wooden boards, etc.;

2. Deal with the mold species, fix the mold species on the wooden board with sludge, smooth the sludge by hand with water, cut off the excess sludge around;

3. According to the product structure, pattern purpose, the silica gel is weighed proportioned, the proportion between silica gel curing agent is 100:2-2.5;

4. Stir the proportioned silica gel evenly put it into the vacuum machine to vacuum (pump the vacuum to -0.1mpa, so as to prevent the mold bubbles affect the quality. If there is no vacuum machine, the curing agent can be reduced Add ratio to extend the curing time release excess bubbles);

5. Apply the vacuumed silica gel evenly to the mold (generally, you can brush the second layer in about 15 minutes, with the silica gel required for the second layer, repeat the first layer of silica gel 2-3 times);

6. When the silica gel is flowing, stick a layer of gauze on the silica gel. The advantage of this is that it can enhance the strength tear resistance of the silica gel, then apply a layer of silica gel evenly (add a layer of gauze according to the size of the product. Generally no more than two floors);

7. After the silica gel is applied, lay a tenon on the edge close the mold with the outer mold to make the mold good;

8. After the silica gel is cured, the outer mold can be made, the shape of the outer mold is fixed with a wooden board, the adjusted plaster is poured into the mold, the plaster is smeared flat;

9. After the outer mold is completely cured, remove the board, remove the entire outer mold the silicone mold, check the silicone mold, trim the silicone mold with scissors, trim the plaster outer mold;

10. After the production of the silicone mold is completed, it can generally be put into production after 24 hours.

Note on operation of plaster line mold silica gel:

1. Use clean operating tools to prevent silica gel mixing with impurities affecting curing;

2. The amount of curing agent added should depend on the temperature, it will decrease if the temperature is higher. Excessive addition of curing agent will affect the quality of the mold, the silicone mold will become brittle; adding less curing agent will prolong the curing time;

3. Vacuum to -0.1mpa is enough, the vacuum time should be too long to prevent cross-linking reaction of silica gel when vacuuming, causing silica gel to become piece by piece, causing waste of raw materials;

4. After making the silicone mold, store it in a ventilated, cool dry place, put it into production after 24 hours.

Plaster line mold silicone parameters:

color | White/Translucent | |||||

Hardness (Shore A) | 15±2 | 20±2 | 25±2 | 30±2 | 33±2 | 40±2 |

Vulcanizing agent addition (%) | 2-3 | |||||

Dynamic viscosity (mPa.s) | 1.3w±0.2w | 1.7w±0.2w | 2.5w±0.2w | 2.7w±0.2w | 2.5w±0.2w | 1.5w±0.2w |

Tensile strength (MPa) | 2.5 | 2.8 | 3.4 | 4.0 | 3.5 | |

Tearing strength (KN/m) | 16±2 | 19±2 | 24±2 | 25±2 | 21±2 | |

Elongation(%) | 380 | 530 | 410 | 420 | 450 | 180 |

Density (g/cm³) | 1.08 | 1.09 | ||||

Operating time (min) | 30-50 | 30-40 | 30-50 | |||

Curing time (h) | 4-5 | 3-4 | 4-5 | |||

Linear shrinkage rate (%) | 0.3 | |||||

standard packaging | 25kg | |||||

Note: The above parameters are only regular parameters. If you have special requirements, please contact our company; the hardness, viscosity, operating time after curing can be specially adjusted provided according to customer needs.